As a result of the advancement of technology ;

Since the possibilities of using steel bars as raw materials in CNC machines, sliding automatic machines with drives, vertical, horizontal or special machines are increasing,

As a raw material supplier, we aim to provide raw material services suitable for our customers’ sensitive production processes.

We serve our customers in our cold rolling mills with the following steel groups, including decimal dimensions, in length conditions, without runout, with the desired surface precision (within tolerances of h7, h9, h11), clean, bright, scratch-free and ovality-free, optionally with single or double-sided chamfering

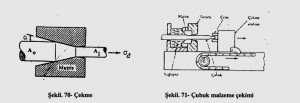

Cold Drawing Process;

Steel bars are passed through molds at room temperature from drawing lines, and the section is narrowed by plastic shaping to obtain a bright surface and precise diameter tolerance.

In order to apply the cold drawing process;

The scale and corrosion on the surface of the hot rolled material must be removed (mechanical cleaning).

The quality of this mechanical cleaning process directly affects the surface quality of the cold drawn product.

In our facility, the Sandblasting Method, which is a mechanical cleaning method accepted all over the world, is applied.

In our cold drawing lines, according to their quality;

- Carbon steel bars

- Transmission bars

- Automatic steel bars

- Structural steel bars

- Cementation steel bars

- Progressive steel bars as well as alloy steels are also produced.

In our cold drawing lines, according to shape and size;

- Diameter between 20 mm and 70 mm main dimensions.

- We can also produce in special decimal diameters or lengths according to customer demand and quantity.

Our standard and tolerance ranges in our cold drawing lines;

We can produce in EN10278 standard

h9, h10 and h11 tolerances.

If you want to get more detailed information, you can contact our Sales department.