Description

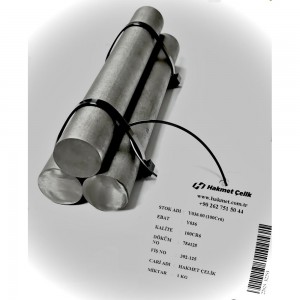

Cementation Steels

Cementation steels are low-carbon, non-alloy or alloyed steels used in the manufacture of parts that are hard and wear-resistant on the surface, softer and tough on the core, and resistant to variable and impact stresses. These properties are gained by impregnating the steel surface with carbon.

They are used in the manufacture of parts such as cementation steels, gears, shafts, piston pins, links, sprockets and rollers, discs, guide bearings, bearings, rollers, some measuring and control instruments, medium strain parts, cutting tools. The use of cementation steels provides the following advantages over the use of high carbon steels, which will give the same hardness value on the surface:

Since the cementation process is applied after the part has partially or completely taken its final shape, the part is quite easy to process.

If there are parts to be processed on the surface of the part that do not want to harden, these areas are covered with special paste or electrolytic copper. Since the cementation process cannot affect these parts, it is easily processed afterwards. After the cementation process, there are very few distortions that may occur during hardening, as the core area will maintain its softness. The internal parts of cemented steels can be easily machined. Cementation steels are often cheaper than high carbon steels in tool steel condition, which can give the same hardness on the surface. However, choosing the right cementation steel and the right cementation process requires attention and experience. The good result of the cementation process (reaching the desired cementation depth and hardness) is closely related to the internal structure cleaning of the steel used. Internal structure cleaning is the process of removing the gases (hydrogen, oxygen and nitrogen) melted in the liquid steel and removing the oxide sulfide inclusions. The depth of the cement can be between 0.2 – 1.5 mm. The percentage of carbon in cementation steels varies from 0.10 to 0.20. The most important feature of this group of steels is its‘ toughness‘ feature due to low carbon. If the percentage C is high, deep hardening weakens the toughness property. Low carbon; low body hardness and high toughness is preferred where desired; high carbolic species; high body hardness is preferred where desired. Higher alloy steels should be used as the section grows. They can also be defined as gear steels by their use. Important features in teeth: wear and fatigue resistance is required to be high. As the surface hardening depth increases, the fatigue life increases. The element that most affects the fatigue strength is the amount of “”C””.

Reviews

There are no reviews yet.