Description

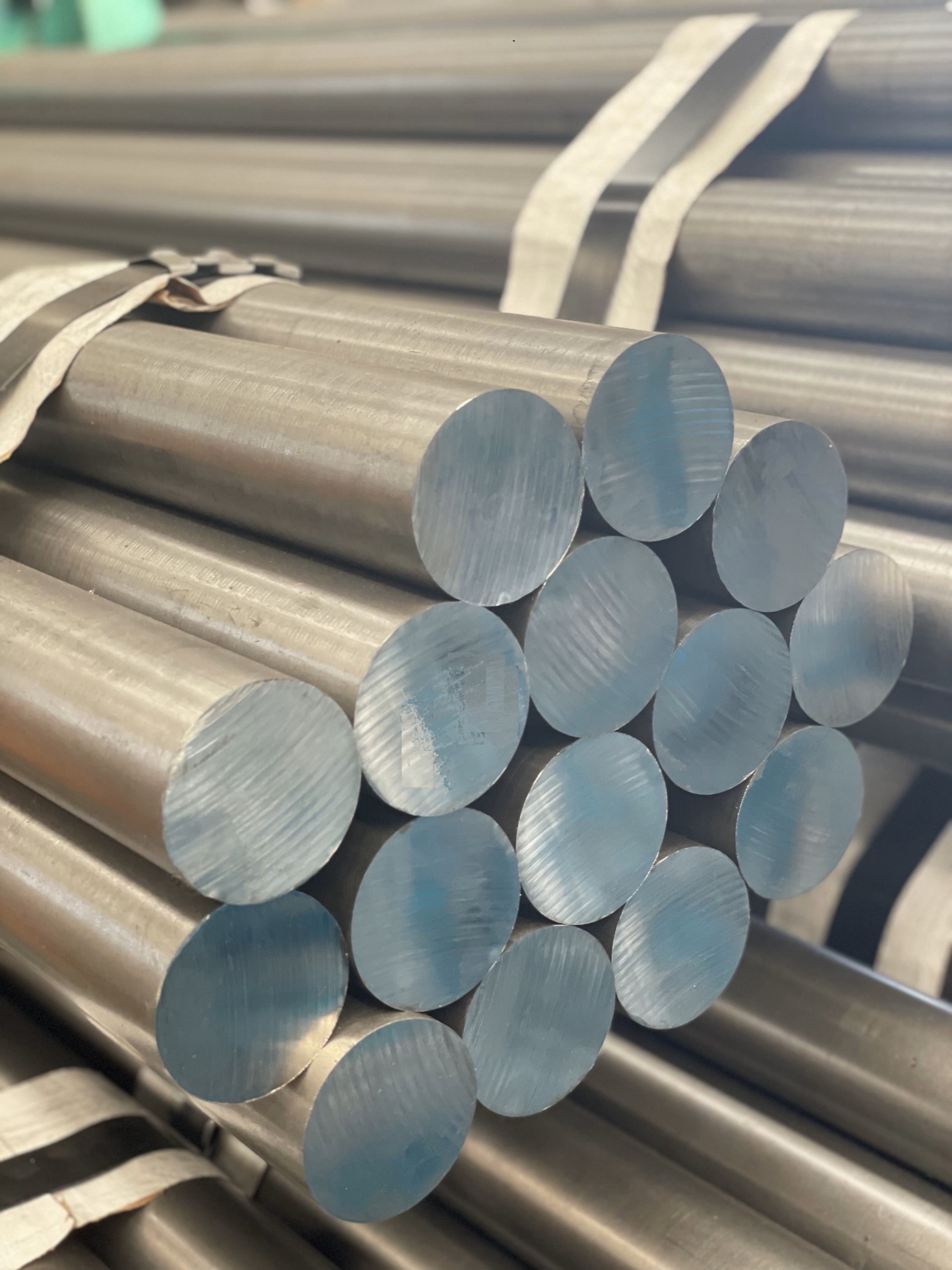

Tempered Steels

Tempered steels, are non-alloy and alloy machine manufacturing steels the chemical compositions of which are suitable for hardening especially due to carbon amount and show high toughness at a certain tensile strength at the end of the tempering process.

In addition to its hardenability properties, high strength and ductility are also desired in tempered steels. In order to obtain a sufficient level of hardness, tempered steels contain relatively high carbon to others. Since the hardness depth is the most important criterion for thick-sectioned parts, these parts are made of alloyed tempered steels.

In the selection of tempered steels, part sizes and strength values are at the forefront. Unalloyed tempered steels can only be efficient in small cross-sectional parts. For parts with thick sections, the homogeneity of the hardness distribution depends on the alloying of the steel. Changes of hardness distribution according to material alloys can be observed with jominy test results. In simple terms, the Jominy test refers to the hardening values at distances to the cooled end by cooling only one end of a rod-shaped material heated to the hardening temperature.

Tempered steels can be hardened by flame and induction, or they can be hardened by flame and induction after breeding. In the selection of the material to be heat treated in this way, besides the chemical composition, the hardness value to be obtained on the surface and the hardening depth are taken into account. While the hardness depth in unalloyed steels can be 3-4 mm. In alloy steels, this depth reaches 10-12 mm. In addition, it is more suitable to use high carbon-low manganese Cf quality steels, as they will create a high manganese cracking hazard during induction hardening. In addition, the reduction of the risk of cracking is closely related to the small grain structure of the material.

The tempering process is described as a combination of first a hardening and then damascening, after which the high toughness property will ultimately be imparted to the steel part. Because of the superior mechanical properties that tempered steels gain at the end of the tempering process, they are used in a wide range of areas, such as manufacturing various machine and engine parts, forged parts, various bolts, nuts and studs, crankshafts, axles, control and drive parts, piston rods, various shafts, threads. For this reason, tempered steels are the highest type of steel produced and used after construction and unalloyed steels.

Reviews

There are no reviews yet.